Pipeline Leak Detection Systems

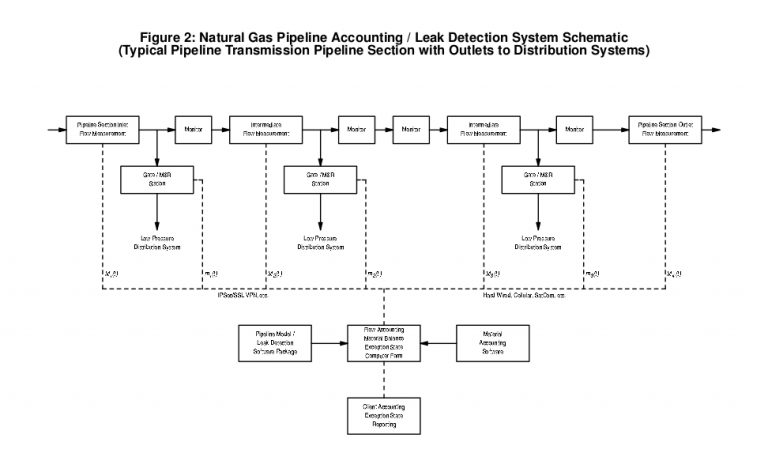

A leak is by definition the loss of material from a pipeline. Accordingly, the determination of a pipeline’s mass (or standard volume) balance is the only truly rigorous method of real time leak detection. This becomes a somewhat complicated task in compressible fluids, requiring excellent instrumentation, a coherent calibration strategy, on-line communications, and a complex software system that iterates the continuity, momentum, energy, and state equations for the determination of system balances.

The mass balance method requires/provides excellent flow accounting, and can be used in pipeline sections that cannot be “pigged”, or is not amenable to aerial or acoustic survey, etc.

The high accuracy and resolution of QUANTUM DYNAMICS’ aerospace flow instrumentation led to their discovery by the pipeline industry. Subsequently, the “LeakX” software package was developed cooperatively with QUANTUM TECHNOLOGY (Houston) and Texas A&M University. The efficacy of these systems is described as “outstanding for leak detection in gas [pipe] lines” in the pipeline industry’s standard desk reference Pipeline Rules of Thumb Handbook, J. Flow Metrology, ISA Instrument Engineer’s Handbook,, etc., as well as in a requested white paper on the Pipeline Safety Trust’s website, www.pstrust.org/docs/massbalance_ld.pdf

Note that even a single pipeline incident – see photos – causing human or environmental damage can wipe out years of profit and lead to significant resistance to any future pipeline expansion projects. Early detection – and prioritization – of pipeline leakage, allows the planning and timely remediation of defects – which is always significantly less expensive than repairs under the duress of catastrophic blow-outs / failures.