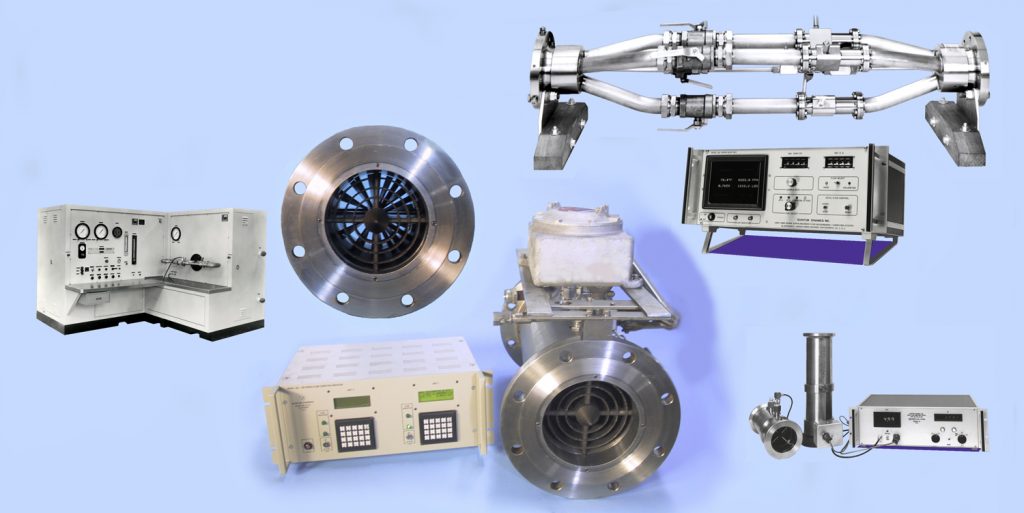

Liquid, Gaseous, and Two-Phase Cryogenic

Flow Measurement Systems

As the pre-eminent supplier of aerospace flow instrumentation systems, QUANTUM DYNAMICS pioneered – and patented – many advanced flow metrology technologies.

A 1999 worldwide survey of 34 manufacturers of flow instrumentation by the French Atomic Energy Commission concluded: “The turbines are of special interest because of their accuracy, their sensitivity at very slow speed and their short time of response. Only 6 turbine manufacturers would be able to answer since they are used to developing tailor made solutions. All 6 are American small/medium enterprises specializing in turbine flowmeters. QUANTUM DYNAMICS clearly appears to be the VERY FIRST in terms of quality.”[sic]

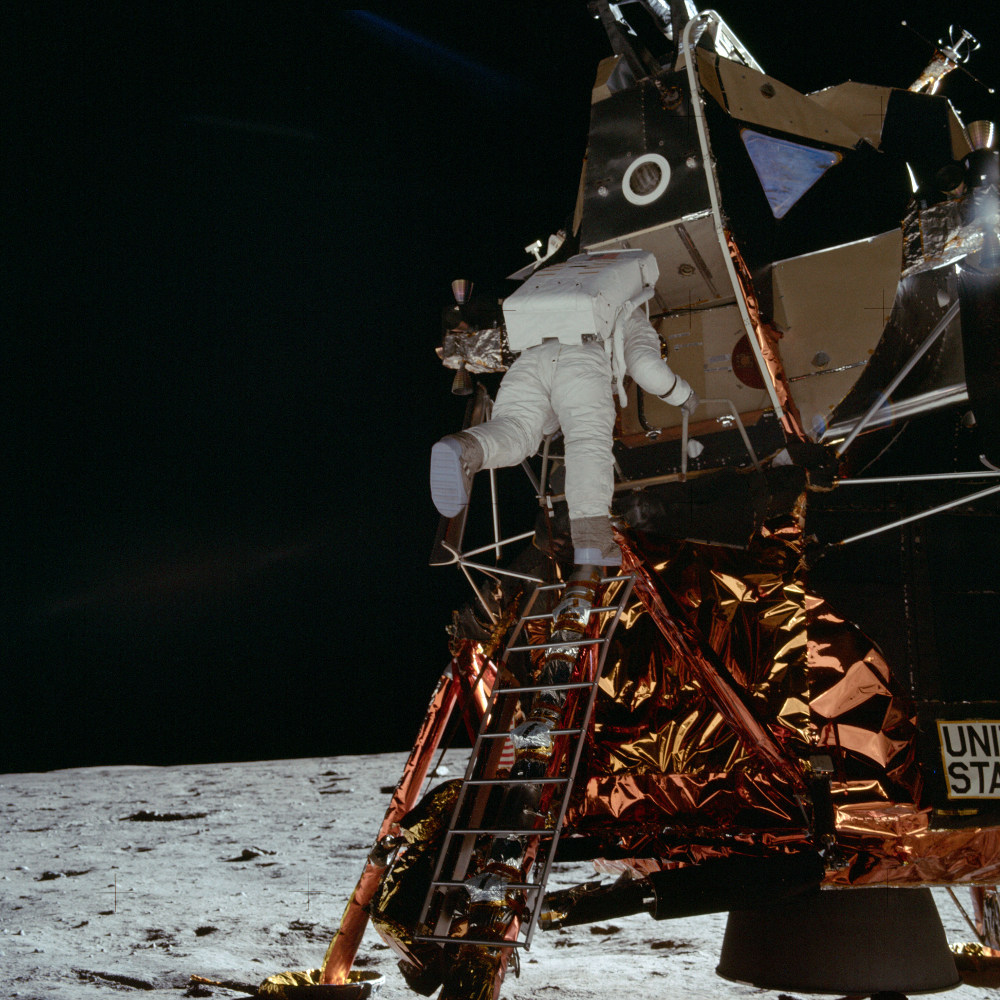

QUANTUM DYNAMICS systems were/are used in many extremely critical flow measurement/control applications, including the Apollo missions mid-course correction and balanced flow/thrust lunar landings – and the Apollo 13 rescue trajectory; jet engine test stand fuel efficiency improvement; pilot oxygen diluter-regulator test stands, space station environmental control; two-phase cryogenic fueling of launch vehicles; on-orbit 0-G LH2 refueling; nuclear materials accounting (D²O “heavy water”, tritium gas); etc. The systems used in “man rated” on-orbit life support applications have MTBFs of 28 – 70 years, calculated per military standards.

The resulting instrumentation systems are now finding widespread use in commercial liquid, gaseous, and 2-phase cryogenic flow measurement applications where the highest levels of accuracy and reliability are required, especially in those areas requiring improved efficiency, minimization of emissions or leaks/losses, etc. To support these systems, Quantum Dynamics has designed advanced state-of-the-art Calibration Systems based on the fundamental properties approach.